Today, diagnostics is a lengthy process with testing turnaround from sample acquisition, transport to a laboratory, testing and reporting of results typically taking several days in developed countries with costs per tests of the order of £10. For underdeveloped countries, the situation is much worse or even non-existent. Currently there is a technology push to develop point-of-application sensors, current clinical examples include pregnancy tests and glucose monitors but research developments aim to extend this to detect any significant analytes of interest, for example protein stroke markers, bacteria in water, etc. Requirements for such technology is low cost (they need to be disposable and widely applicable), fast response (results are required within minutes) and highly sensitive (as some analytes of interest are of very low concentration). This recent push towards point of application testing is bringing a new emphasis to this area of research, using integrated systems, where carefully optimised functionalisation of the sensor is supported by associated electronics, fluidics and separation technology. The potential for an extensive breakthrough of disruptive sensor technology is a real possibility.

There are many key issues when developing biosensor systems, these being:

- Design and modelling of the biosensor – do you go for an electrical, electromechanical or an optical design? What materials should you use, traditional ones such as silicon or more exotic ones such as piezoelectric?

- Biosensor fabrication – will you make your sensor from traditional approaches such as microfabrication in a clean room or utilise new manufacturing technologies such as rapid prototyping?

- Surface functionalisation – you will ultimately need to attached your biological molecules of interest to your sensor surface, what are the best biochemistry approaches to accomplish this?

- Sensor and surface characterisation – how do you check your sensor surface, both physically and chemically, at microscale and nanoscale resolutions?

- Signal processing – although we have multimillion pound laboratories to measure biosensors, ultimately they need to be measured through commercially viable electronics, for example something the size of a mobile phone, how will we do this?

- System integration – what other components do we need to make the biosensor into a sensing system, for example how do you introduce the blood sample to the sensor, do we need a microfludics system developing?

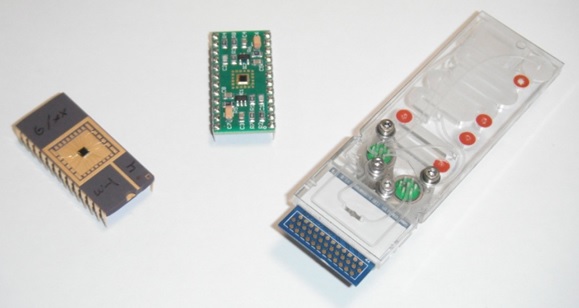

(Left image) A sensor mounted in a dual inline package for initial characterisation. (Centre image) A mounted sensor together with its signal recovery electronics. (Right image) Sensor and corresponding electronics mounted into microfluidic packaging.

There is a vast array of research issues to address with a host of options for solutions and therefore answering all these questions takes a multidisciplinary team. For an individual PhD project, you would look to address one or two of these points, for example you may wish to design and fabricate a biosensor, and then integrate your work with other members of the team.

The opportunity to fabricate devices comes from our in house facilities and collaborations with national and international fabrication facilities. Through these routes, you will be able to design and fabricate devices optimised for high susceptibility to biomolecular interaction. For characterisation, extensive facilities are available within the University for such research. A multimillion pound national surface analysis facility is housed within the School, currently home to two state-of-the-art lab-based XPS spectrometers and soon to be enhanced by a recently awarded £2.7 Million grant [2] to incorporate imaging and chemical analysis at nanometre spatial resolutions. The School is also home to a £1 Million state-of-the-art MEMS characterisation lab consisting of surface profilometry, laser vibrometry, Raman spectroscopy and a suite of electrical characterisation equipment. Biological characterisation equipment for projects is housed in a class 2 biolab within the Institute of Cellular Medicine allowing for measurements of clinically relevant analytes. The group is involved in the UCL led £16M EPSRC IRC in Early Warning Sensor Systems for Infectious Diseases and thus a route is in place for deployment of any developed sensor technology.

The bioMEMS group at Newcastle University has an extensive track record of biosensor development, for example [3-6]. With working in a multidisciplinary team for over a decade, we have seen both the technological and training benefits gained from integrating engineering and Medical Sciences. For example, previous members of the research team have gained prestigious jobs at a range of organisations throughout the world: EPFL (Switzerland), Pusan National University (South Korea), Dublin City University (Eire), IMB-CNM, (Spain), Microsaic Systems Ltd (UK), Nanosolar (USA). The broad range of techniques and collaborations involved gives applicants an ideal networking environment in which to develop their career.

Projects give training to PhD students which broaden and deepen their knowledge of their respective fields. Each project allows the student:

- to deepen their theoretical understanding of their chosen subject area whilst widening their knowledge base

- access to world class facilities allowing for hands-on experience of state-of-the-art techniques and equipment

- opportunities to present their work at prestigious conferences and publish their findings in peer reviewed journals

- networking opportunities to establish academic contacts and develop career progression

- an opportunity to contribute to a step change in sensor technology that would benefit people around the world.

Applicants should hold (or expect to shortly obtain) a very good honours degree (equivalent to a UK 1st class or upper 2nd honours degree) in engineering, physics, chemistry or biochemistry. Informal enquiries about any of the projects may be made by emailing Dr John Hedley (John.Hedley@ncl.ac.uk) in the first instance. We look forward to welcoming you to the group.

References

[1] National EPSRC XPS Users’ Service (www.ncl.ac.uk/nanolab/research/themes/nexus)

[2] Ion-Beam-Analysis User’s Service for Interface Characterisation and Engineering – NEIBUS (www.epsrc.ac.uk/newsevents/news/2013/Pages/85million.aspx)

[3] Ismail et al, “The fabrication, characterisation and testing of a circular diaphragm mass sensor,” J. Micromech. Microeng. 18 025021, 2008.

[4] Suarez et al, “Biomolecule Patterning on Analytical Devices: A Microfabrication-Compatible Approach,” Langmuir 26 6071-6077, 2010.

[5] Ortiz et al, “Issues associated with scaling up production of a lab demonstrated MEMS mass sensor,” J. Micromech. Microeng. 22 115032, 2012.

[6] Burnett et al, “Electronic detection strategies for a MEMS based biosensor,” J. Microelectromech. Syst. 22 276-284, 2013.